10.7 million tonnes of starch are produced in Europe, mainly from maize and wheat. It can be used in its natural form or after modification in blends. In addition to food packaging applications, pure starch can be used as a loose-fill material.

Starch can be used as a compound partner to increase strength and reduce costs. The addition of starch improves the biodegradability of the material and increases its degradation rate. The starch content in these compounds can be up to 70 percent. In this case, the thermoplastic starch is often mixed with water-repellent, biodegradable polymers.

Composition of starch compounds

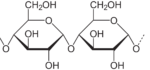

Starch compounds consist of two phases: the continuous hydrophobic polymer phase and the disperse hydrophilic starch phase. Together, they form a waterproof starch plastic. Most flexible starch compounds contain biodegradable polyester as a blending partner.

The largest manufacturer, Novamont, uses reactive extrusion to produce starch compounds in Italy from the main raw materials maize starch and copolyester, some of which contain components from vegetable oil. Novamont’s production capacity has been increased to 150,000 tonnes per year thanks to its factory in Patrica.

Symbol legend

![]() positive evaluation

positive evaluation

![]() Evaluation in individual cases

Evaluation in individual cases

![]() predominantly critical evaluation

predominantly critical evaluation

Kontakt

In the following, you will find a selection of materials manufacturers.

Biotec GmbH & Co. KG

The German manufacturer Biotec GmbH & CO KG has a capacity of over 25,000 tonnes and specialises in compostable plastics made from starch compounds based on polylactides (PLA), polyhydroxyalkanoates (PHA) and polybutylene adipate terephthalate (PBAT). Bioplast 900 packaging, which is 69 percent bio-based, is suitable for hot filling and products such as yoghurt. Other Bioplast applications include bin bags and carrier bags with a bio-based material content of over 50 percent from potato starch and PLA, agricultural films, and packaging for the cosmetics and food sector (e.g. fruit and vegetable bags). PHA is used to produce injection moulded items such as coffee capsules. In the case of water-based contents, water vapour barriers are used.

KINGFA Science & Technology Co. Ltd.

The Chinese company KINGFA Science & Technology Co. Ltd., with a holding company in Wiesbaden, is the world’s largest producer of modified plastics such as carrier bags, bin bags, mulch films, ropes, office materials and disposable items such as gloves and cutlery. Their Ecopond production with a capacity of 30,000 tonnes, which is distributed worldwide, is worthy of special mention. KINGFA, with all its holdings, produces 1,500,000 tonnes of packaging per year.

Loick Biowertstoff

The Loick Group has been producing various fillers from renewable raw materials since 1994.

Novamont S.p.A.

Novamont processes conventional maize starch from Cargill in Terni (Italy) into its Mater-Bi® product. These are various granules made from maize starch, vegetable oil, beet sugar (bio-butanediol) and polylactides, which form complexes by reactive extrusion.

The properties of the various types of Mater-Bi® differ in many ways. In terms of mechanical characteristics, the range extends from products with a low modulus of elasticity and very high toughness to stiff products that tend to be brittle. Optically, the range extends from milky to transparent materials. All commercial types can be processed with the same machines as conventional plastics, e.g. blown film extrusion, film casting, extrusion, thermoforming and injection moulding. The annual capacity is 150,000 tonnes (in 2019).

Rodenburg Biopolymers

This dutch company produces bio-based, degradable biopolymers:

Solanyl®: based on potato starch, for carrier bags and non-food applications

FlourPlast®: Additive for compounders for PLA, PHA, PCL PE, PP

Optinyl®: Additive for compounders to improve their properties

Rodenburg Biopolymers is cooperating with the initiator Taghleef Industry and Mondi on the new bio-based packaging “Nativia Ness”. Nativia Ness is made of potato starch and PLA and is being tested by Mars Inc. as a new packaging. The annual capacity is 60,000 tonnes.

The Gaialene® range of starch compounds are films or blown containers for cosmetic products and foamed products for protective packaging. The bio-based content exceeds 50 percent. The packaging is not biodegradable and has similar properties to PE or PP.

Agrana

With its AMITROPLAST product family, the Austrian company AGRANA produces tailor-made thermoplastic starches for extrusion, film blowing, injection moulding and 3D printing. In addition, AGRANA’s AGENACOMP product range includes bioplastic compounds that contain up to 50% renewable resources and are suitable for home composting.

The following is a non-exhaustive alphabetical list of the converters in the starch compounds segment considered essential by the project team.

Klöckner Pentaplast

Klöckner Pentaplast, in collaboration with Plantic Technologies Limited, distributes Biofilm™ TPS films (rigid starch-based thermoplastic films) for retail packaging. The company operates a centre for application support.

Wentus Kunststoff GmbH

Wentus is a German manufacturer specialising mainly in the production of compostable organic waste bags made of starch (percentage of the range > 90 percent). It also produces packaging for fruit and vegetables. The range also includes packaging made from bio-PE.

Limagrain FR

French manufacturer of starch-based materials from cereals. The packaging material Biolice is mainly used for sack goods (cement packaging, bags, pouches, etc.) as well as for mulch films, trays and injection-moulded items. Biolice is industrially compostable according to DIN EN 13432.

Starch compounds are generally well suited for dry, non-hygroscopic products (e.g. lentils). They have a high water vapour permeability. Therefore, they are currently not suitable for rice and pasta, which require a higher water vapour barrier.

Foils/bags: Carrier bags, bags for hard fruit or vegetables (e.g. carrot and potato bags), flowpack film

Composites for packaging: e.g. for coffee

Thermoformed trays for fruits and cups

Bottles: Only in combination with other polymers. The starch compounds are used as a coating.

Catering: plates and cups coated with Mater-Bi®, cutlery

Other applications: bread bags made of paper coated with starch compounds, applications outside the packaging sector (e.g. lids, nappy films), coated paper and cardboard, injection-moulded plastic items for vegetable growing, mulch films, organic waste bags

Well suited for dry, non-hygroscopic products (e.g. lentils). Currently not yet suitable for rice and pasta, as the water vapour barrier is low. Hence, the material has a high water vapour permeability.

The biopolymer database lists the material properties of starch compounds according to use.

The main ingredients are maize and potatoes. Other ingredients include vegetable oils and sugar. Various raw materials can be used as a source of sugar, e.g. barley, cassava, wheat, potatoes, sugar beet or sago. Experiments are also being carried out with agricultural by-products or residues.

Sustainability criteria

1. Ecology

For the ecology criterion, seven sub-criteria (parameters), which are considered essential for organic food producers, have been included in the assessment: land use/competition for food, environmental compatibility, certifications (cultivation and processing), genetic engineering, end of life (recycling, composting), life cycle assessments and bio-based content.

Currently, it is mainly maize and potatoes which are used for the production of starch compounds. The cultivation of maize and potatoes as the raw material for the production of one tonne of starch blend is very similar, requiring 0.08 (or 0.05) hectares and 0.10 (or 0.06) hectares respectively. For all raw materials, yields can vary considerably from region to region.

Processing routes for the production:

Maize as a raw material

Input: 0.08 hectares (equivalent to 0.54 tonnes of maize) → Output: 1 tonne of starch compound (50% TPS)

Potatoes as a raw material

Input: 0.10 hectares (equivalent to 2.13 tonnes of potatoes) → Output: 1 tonne of starch compound (50% TPS)

In the case of blends, the land requirements of all biogenic raw materials used must generally be taken into account.

Cultivation of maize

Maize has high nutrient requirements (especially nitrogen) and, due to its slow development when young, a low ability to compete with weeds. The high nutrient requirements can lead to increased leaching of nitrate into the groundwater at certain times of the year, e.g. after harvesting, or when no undersown crops have been planted to utilise the residual nitrogen in the soil. Furthermore, herbicides and sometimes insecticides are also used.

There is also a risk of soil compaction and erosion (depending on the location). Erosion is encouraged by cultivation in rows and without undersowing.

Cultivation of starch potatoes

Potatoes need a lot of potassium compared to other agricultural crops. The nitrogen requirement depends on the variety, site conditions and expected yield. In conventional cultivation, it is between 140 and 156 kilograms per hectare.

Use of starch and vegetable oils at Novamont

Novamont uses conventional maize starch from Europe. Novamont physically modifies the maize starch and uses it in its natural form as a polymer in Mater-Bi®. No microorganisms are used in this process. Some of the Mater-Bi® types sold contain maize starch and biodegradable polyester as their main components.

Since Novamont has very high quality requirements for the starch used, only starch of certain qualities can be processed. They obtain these qualities from the starch supplier Cargill. The possibilities of influencing an environmentally friendly cultivation method are very limited due to the small quantities purchased. A majority of the starch produced in Germany for non-food purposes is used in the paper industry.

Biodegradable polyester is used to ensure the flexibility of Mater-Bi® films. Vegetable oils (no soya oil and no palm oil) are sometimes also used to produce the polyester.

For the production of oil plants are cultivated in the company’s own projects in Sardinia. An industrial processing plant utilising vegetable oil has been established in Porto Torres, Sardinia. A further requirement is that the press cake produced during oil extraction should be usable as fodder.

A sustainability report is available.

Here, you will find a paper by Novamont on the relationship between food production and raw material production using bio-based raw materials.

Novamont

The company is ISCC PLUS, ISO 9001, ISO 2015, and OHSAS 18001 certified.

![]()

ISCC PLUS goods are available and can be requested directly from the manufacturer.

The product Mater-Bi meets all important standards for biodegradability and compostability worldwide.

Biotec

The company Biotec is certified according to the following systems:

DIN EN 13432 (biodegradability)

ASTM D6866 (bio-based carbon content)

ASTM D6400 (compostable and biodegradable materials)

ISO 14001 (environmental management)

Wentus

The company Wentus has certified its products according to DIN EN 13432 (industrial composting within 90 days).

The starch used in starch blend plastics is produced without the use of genetically modified organisms (GMOs).

![]() However, starch compounds with PLA require GMO testing.

However, starch compounds with PLA require GMO testing.

Novamont

Some types of Mater-Bi® contain PLA and others do not contain PLA. The percentage of PLA in the granules varies according to the type. No GMO cultivation is used for the PLA-free blends. For starch blends with PLA, it should be clarified in advance whether the PLA was produced from raw materials without GMO plants. GMO-free goods (manufacturer: Total Corbion PLA) are available.

The buyer can determine this within the framework of an individual regulation.

![]()

The material recycling of starch compounds has not yet taken place on an industrial scale due to the small quantities available.

Composting of food packaging is currently prohibited under the German Packaging Act and the Organic Waste Act. Hence, the reason why it is categorised under “assessment in individual cases” (yellow) is the legal situation with regard to composting in Germany and the lack of a recycling system, rather than the end-of-life options offered by the manufacturers.

The company holds compostability certification according to DIN EN 14995 and/or DIN EN 13432. For the Mater-Bi® film types, degradation in seawater has been proven: > 80 percent in 220 days. Depending on the type of material, home composting or industrial composting is possible.

The recycling of unused packaging is possible at any time. The packaging can be regranulated. Food producers can return leftover film to Novamont for this purpose. It can then be used to make waste bags or dog excrement bags, for example.

Biotec

Biotec has carried out trials with its own starch compounds to investigate possible effects on existing PE material flows in recycling systems. In addition to the starch blend, the following non-PE plastics were also selected for mixing with recycled PE: PP, PS and PET. The starch-based Biotec product BIOPLAST GF 106/02 was used as a biodegradable material. The internal investigation report on the mechanical recyclability of PE films, which were mixed with BIOPLAST or the other plastics in varying proportions (2, 10 and 50 percent), yielded the following results:

- PE-based films could be produced with all materials tested, except PET.

- Depending on their proportions, all materials have more or less impact on the mechanical film properties of PE.

- Compared to PP and PS, BIOPLAST was found to have similar to equivalent mechanical performance.

- BIOPLAST admixtures of up to 10 percent in PE formulations do not, in the company’s experience, pose any problems with regard to the mechanical properties of most film applications.

The company regularly carries out internal composting tests. It has also taken part in a test on the degradability of bioplastics in seawater. Biotec is certified according to various systems for biodegradability.

Novamont

The company Novamont has published life cycle assessments on fertiliser consumption in the production of cutlery and mulch films from its raw material Mater-Bi®. In addition, a life cycle assessment is available for fruit and vegetable bags made of Mater-Bi® in comparison with bags made of paper and polyethylene.

For the processing of the raw materials into granulate, life cycle assessments are prepared internally by employees. In this manner, weak points in the life cycle can be identified and optimisation potential can be realised for new types. For the oils, a comparison with traditional plastic films is planned. An EPD (Environmental Product Declaration) for the Mater-Bi® film with data on the CO2 footprint, energy and water consumption in the production of Mater-Bi® films and a sustainability report are available. Where greenhouse gases and energy are concerned, improvements have been achieved compared to previous years.

Wentus

Wentus does not provide a life cycle assessment. A CO2 footprint was compiled for internal purposes. The differences in terms of energy consumption during processing are relatively small in comparison to traditional plastics. The bioplastics are processed at slightly lower temperatures.

![]()

The bio-based percentage of starch compounds varies considerably and can be seen in the product data sheets or on the websites of individual manufacturers.

Specific values are available from the following companies:

Novamont

According to Novamont, the Mater Bi® film types have a bio-based content of 25–70 percent. Starch can only be used to a certain extent; otherwise, the film becomes too stiff. Loose fill packaging materials have a bio-based content of over 90 percent, while injection-moulded types have a bio-based content of over 70 percent.

Biotec

Depending on the formulation, a bio-based content of 20–100 percent is achieved, according to Biotec. For blown film products the bio-based content is 20–51 percent, and for injection moulded products 60–100 percent. The following contents are stated for BIOPLAST products: BIOPLAST GF 106/02: 23 percent; BIOPLAST 500: over 50 percent; BIOPLAST GS 2189: 69 percent; BIOPLAST TPS: 100 percent. The last product uses thermoplastic starch with plasticisers (glycerine, sorbitol), although the range of applications is very limited. At present, the material is only used for capsules with food supplements.

Wentus

Depending on the material, a bio-based content of 30–70 percent is achieved, according to Wentus. To date, the bio-based content of fruit and vegetable films has been below 50 percent, but a proportion of well over 50 percent is set to be achieved in the next few years.

2. Social compatibility

For the social compatibility criterion, the assessment refers to the existence of social standards in cultivation and processing. These can be internationally valid guidelines, national legal standards or private sector standards. The social standards of the country from which the raw material originates or in which the processing takes place are used as a basis for the assessment.

Novamont

Novamont sources most of its renewable raw materials from Europe. This means that EU social standards apply to cultivation. The company is certified according to the ISCC PLUS standard.

Novamont has an “Ethical Code“ for its relations with employees, customers, the public and suppliers.

Biotec

This company sources its raw materials from Germany and France. This means that EU social standards apply to cultivation.

The manufacturers of starch compounds produce in Europe. This means that EU social standards apply.

Novamont

Novamont produces in Italy (Terni). The company has an “Ethical Code“ for its relations with employees, customers, the public and suppliers.

Wentus

This company produces in Germany (Höxter). Wentus is certified according to the GKV Code of Conduct.

3. Safety and technology

Product quality must be guaranteed. The packaging must not react with the product and must prevent it from reacting with the external environment. Regarding technology, the technological processability of the packaging material is evaluated. Can it be processed on standard machines? What adjustments, if any, must be made? Are there any compromises in terms of quality, processing speed or durability?

Thermoplastic starch (TPS) is used as a niche product in the pharmaceutical sector. The strong hydrophilicity of TPS reduces the application possibilities, as in most cases a blending with other materials (usually biodegradable polyesters) is necessary to obtain the desired properties.

Also in the case of starch-based packaging materials, the respective application must be reviewed to ensure that the stability of the packaging material is guaranteed. To obtain the desired material properties, various additives are used for blending, which can cause different interactions.

![]()

Depending on the planned application, the additives used must be tested or confirmation must be obtained from the manufacturer that testing has been carried out for the respective planned application.

Starch-based packaging materials are often biodegradable.

Novamont

On the condition that confidentiality is assured, the manufacturer Novamont will send the declaration of conformity in accordance with the Plastics Implementation Measure (PIM), in which the SMLs (specific migration limits) are stated.

Biotec

For BIOPLAST, the manufacturer provides detailed material properties and application possibilities on the website. A declaration of conformity must be requested separately. BIOPLAST 500 is manufactured without the use of plasticisers.

Processing can be carried out on traditional processing machines. It must be taken into account that the processing must be carried out at lower temperatures compared to mineral oil-based packaging materials and that the production volume is slightly reduced. Lower sealing temperatures must be taken into account.

![]() Due to the low heat deflection temperature, the packaging has only limited heat stability (60–80 degrees).

Due to the low heat deflection temperature, the packaging has only limited heat stability (60–80 degrees).

Mater-Bi® can be processed on conventional blown film extrusion lines. Applications include mulch films, packaging films and films for lamination. The manufacturers also offer application consultations for the various fields of application.

Packaging made of starch polymers has increased water vapour permeability. With a value between 200 and 800 g/m²*d (according to DIN 53122), the water vapour permeability of starch polymers is between that of PE and paper. This means that starch-based films reduce water vapour condensation in the headspace of products and offer the possibility of moisture regulation.

![]() The barrier properties can be significantly improved via coatings or lamination.

The barrier properties can be significantly improved via coatings or lamination.

Due to the wide variety of starch compounds, the most suitable packaging material can be selected for the respective application.

Here are some examples of packaging applications.

Starch-based packaging offers good fat barrier properties and good flavour protection. If packaging materials with a good oxygen barrier are required, residual oxygen can be minimised by using an oxygen absorber.

![]()

![]()

![]()

Users should carry out shelf life tests with regard to a longer minimum shelf life. Protective gassing is currently not possible with the starch-based packaging material produced by Novamont.

As starch compounds have been used in various applications for a long time, packaging manufacturers have practical experience with the respective applications.

![]()

However, since the underlying tests are often carried out in close cooperation with food manufacturers, this information is not always publicly available.

In this case, it is advisable to work closely with the packaging manufacturer. A prerequisite for the production of application-oriented blends is the purchase of sufficient quantities.

There are numerous applications outside the field of food packaging. For example, mulch films for agriculture and horticulture offer considerable advantages in practical use due to their biodegradability. Organic waste bags and packaging, as well as nappies and sanitary towels, also benefit from biodegradability.

4. Quality

The quality criterion encompasses the legal requirements for packaging material (section 4.1). According to the German Federal Institute for Risk Assessment (BfR) standards, “quality” means compliance with the legal requirements and BfR specifications for packaging. Ecological and environmental aspects are important criteria for bio-based packaging. Packaging reactions with different goods and thus different stability requirements must be avoided. At the same time, excessive demands can lead to costly, unsustainable packaging. Bio-based packaging can often offer advantages such as biodegradability. Consumers demand transparent and truly sustainable packaging with the same handling quality.

More well-known manufacturers usually have a certified quality and environmental management system.

![]() Interested parties can request the declarations of conformity issued by the manufacturers for the various packaging materials and check them with regard to the planned application. In addition, the following legal requirements apply.

Interested parties can request the declarations of conformity issued by the manufacturers for the various packaging materials and check them with regard to the planned application. In addition, the following legal requirements apply.

Due to the low barrier properties and short shelf life of starch compounds, it is essential to know the product properties of the product to be packaged in detail.

![]() Low water activity values and a short best before date are important product requirements.

Low water activity values and a short best before date are important product requirements.

Laminated paper can be recycled with product residues via composting if the disposal company has agreed to this. For perishable products with lower barrier requirements, laminated films can be used. Typical examples are fruit and vegetable packaging. Sample applications are listed on the websites of the materials manufacturers.

Due to the highly varying customer requirements, coordination with the manufacturer is very important. In each individual case, it must be checked whether others have already had experience with a particular application.

![]()

![]() The consumer requirements regarding safe packaging are guaranteed. For products with a longer shelf life, tests should be carried out in advance on the shelf life of the packaging material.

The consumer requirements regarding safe packaging are guaranteed. For products with a longer shelf life, tests should be carried out in advance on the shelf life of the packaging material.

Thermoplastic starch (TPS) can be used for a wide range of applications for dry products with short best before dates. It is also used for the production of plastic shopping bags. Stability can be significantly increased by blending. However, if the material is to be biodegradable, there are limits to its stability. Durable and stable packaging materials can be produced through blending. The material is more stable and less susceptible to creasing than PLA and can be processed with fast cycle times. You can find more information in the following literature.

![]()

Stability and handling should be checked individually with regard to the products to be packaged.

Use for products with a longer best before date may be possible in exceptional cases after intensive testing.

![]()

![]()

![]() As starch-based packaging has been used in various applications for a long time, packaging manufacturers have practical experience with the respective applications.

As starch-based packaging has been used in various applications for a long time, packaging manufacturers have practical experience with the respective applications.

![]()

However, since the underlying tests are often carried out in close cooperation with food manufacturers, this information is not always publicly available.

The advantages of starch compounds include their biodegradability, as they are easily compostable when used as catering packaging, for instance.